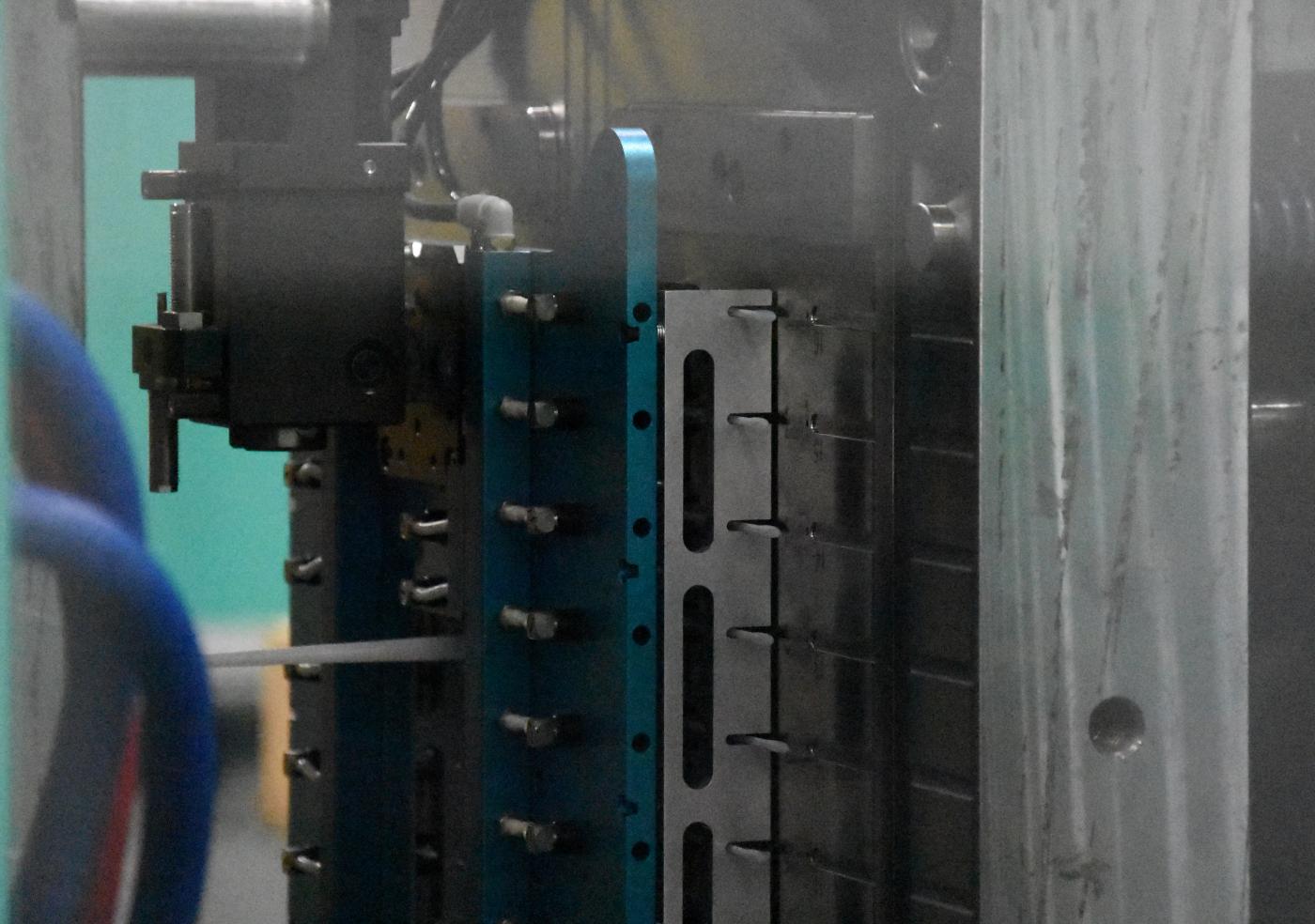

Teel has chosen to partner with Arburg as its primary provider of injection molding technology. We currently have seventeen machines ranging from 110 to 350 ton, with the majority in the 165 to 275 ton range. Our machines also feature secondary operation automation cells such as laser marking, automated packaging capabilities, and many are equipped with linear robots or a servo sprue picker for fast part and runner removal.

We commonly run four to sixty-four cavity molds, featuring hot and cold runner systems. Our standardized approach to process development, along with a careful selection of machine and auxiliary equipment for your application, will minimize part-to-part variation and ensure quality product every cycle. Contact us today to see if your part will run on our machines!

Below is a detailed list of machines on our floor:

BACK TO INJECTION MOLDING PAGE